Revolutionary rotary piston machines

for pumps, compressors, motors with new work processes.

A fundamental breakthrough in the design of piston machines with

the simplest but most powerful piston actuating mechanism ever created.

Six screws, with sealing elements function as pistons, are screwed on a plate/shaft being one solid piece without any connecting bearings between pistons and drive shaft.

Summary:

New pumps, compressors, water hydraulic motors are introduced - based on the Wolfhart Principle - a new rotary piston machine combined with new

work-processes.

The physicist and inventor Wolfhart Willimczik created a rotary piston machine without any bearings in the power train and with only rotating pistons.

A stroke motion without mass forces is finally realized! Friction is eliminated or drastically minimized respectively that such machines are able to

run a priori without any lubrication - even at high pressure. It is the ideal machine for many applications.

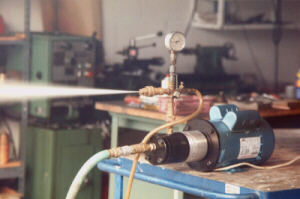

Video 1.4

A Pump (2GPM at1000PSI) running in the work shop of the inventor.

Compare the sound of this pump with the one of a formula one racing car; it is the same frequency. (6 pistons at 3400rpm sounds

like 6x 3400rpm=20400rpm) You hear the fastest piston pump letting all others on the market far behind.

The reason lies in the better kinematic of this pump. In contrast to common water piston pumps

with valves the fluid runs continuously through the pump in a circular orbit and the velocity will never be zero with reversing the direction.

The secret of the first bearing-less, pulling, self aligning piston actuating mechanism

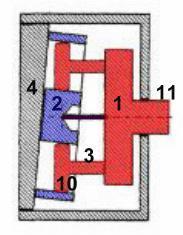

1 - Piston Rotor/Plate ....2 - Cylinder Rotor/Block ....3 - Piston Rod/Screw .....4 - Carbon Control Plate

5 - End Plate .... 6/7 - In/Outlet ....8 - Mechanical Shaft Seal.....9 - Electrical Motor....10 - piston....11 - shaft

6 spherical pistons and the cylinders rotate with an angle at 5° to each other.

To see is here the pressure side, where the pistons do not work. (the cylinders are cut open.

More Videos of the Wolfhart Principle

Basic principle:

The aligned rotation of pistons and cylinders at a small angle generates a relative stroke motion between them in the co-rotating reference system. The pistons, passing over the inlet port, suck in and push to the same time backwards against the high working pressure in the housing. Pistons and cylinders only rotate and are counterbalanced. There are no mass forces. Piston rods, piston plate, and drive shaft are one solid piece without any bearings between them. Hydraulic forces are all hydraulically compensated.

This principle is an axial piston type - similar to a Bent Axis Pump, but only at first

glance.

In this pump, the cylinder are at a small angle (5°) to the drive shaft and Piston Rotor/Plate.

The connecting rods are screwed on the Piston Rotor/Plate.

The drive shaft, piston plate/rotor (with the pistons), and cylinder block/rotor all revolve.

The cylinder block/rotor has no own shaft. It is guided by the pistons.

The pistons (mostly spherical) are swing able in the cylinders.

The in/outlet ports are semi-circular holes in the Valve Plate.

A short stroke motion and large pistons are characteristic for this design.

In this version, the connecting rods only pull the pistons against the high pressure in the housing.

The pistons must be (are) pressure tight only in one direction and only half the revolution.

Characteristic features

No bearings in the piston actuating mechanism:

The most significant difference to all other piston machines is the absence of any bearing in the power train (between the pistons and a drive shaft).

Piston forces are transformed in a torque without using a single bearing transmitting piston forces. Therefore, the pistons can be enlarged to any

size at any pressure. Piston forces are not more restricted by the limitations of bearings. (The drive shaft is axially balanced.) Kinematic and work

process are unique: A bearing-less piston actuating mechanism with only rotating pistons generates a relative stroke motion between pistons and

cylinders without mass forces normally belonging to it. It is the best kinematic possible. The pistons, passing over the inlet port, suck in and push

to the same time backwards against the high working pressure in the housing. That`s basically the entire pump-process. On the other half of one

revolution the pistons have nothing to do anymore. They could be taken out for this time period. (They are not air-tight in this phase.) All what they

do is moving in the start position for the next working phase. This new work process has numerous dramatic consequences. Piston forces can be

totally balanced. Furthermore, the "compression phase" in the cylinder is eliminated, that means a fluid-gas mixture can be pumped -

even against high pressure. Gas can be compressed almost as high as fluid pressure. Most complete balance of all forces: Oscillating mass forces are

not present. Both rotors revolve around the centers of gravity. The cylinder block is hydraulically balanced by funneling high pressure under the

cylinders which are partially closed for this purpose. The drive shaft, piston plate, and pistons are one piece and are axially balanced by making the

area content of the cross section of the drive shaft (on the shaft seal) equal to the sum of all active piston areas. The hydraulic forces on the

pistons and on the drive shaft compensate each other in axial direction, because the pistons are pushing backwards. Total oil-free operation for

pumps, compressors, water hydraulic motors etc. Friction is dramatically minimized that this rotary piston machine is able to run without any

lubrication - even at high pressure, high volume and high speed. Largest range in volume and pressure: The Wolfhart Principle has no limitations in

the possible range of volume and pressure. The product "volume times pressure" is the highest. There are principles for high volume and

others for high pressure; this principle can both at the same time. A typical application may a water pump for 1000 GPM at 1000 PSI, where no other

principle is suitable.

Largest range of speed:

Some principles must run with a minimum speed, some are not able to run fast. This principle can both. The kinematic of this machine has no

limitations. (The maximal speed will determined by other parameters like the viscosity of the medium etc.)

Highest possible efficiency:

Low friction, low acceleration of the fluid, and large ports etc are the means for a smooth operation and a high efficiency. The tests show that this

new principle has the highest possible efficiency. (Test data are available.)

No lateral forces between pistons and cylinders:

The connecting rods are screwed on the piston plate with an specific angle that in the working

phase of the stroke motion the connecting rods are straitened in the cylinders and lateral forces

minimized. A certain overcompensation drives the cylinder block. That means the cylinder

rotor is hydraulically driven.

Highest possible durability:

Simplicity breeds Durability. This simplest piston principle has also the highest durability.

If foreign particles are coming in, the cylinder block is able to lift up from the valve plate. The

piston sealing elements are also hold in place only by a spring. They can actually stop moving

in the cylinders until the particle is gone.

If one connecting rod should break, the piston remains on the ground of the cylinder and the

pump is still running generating pressure.

High live expectancy:

No bearing is better than the best bearing. If the piston plate is directly attached to the shaft of an electrical motor, the entire pump has no

bearing. The remaining wear on cylinder block and pistons is minimized by eliminating of unnecessary contact pressure.

The cylinder block is hydraulically adjusted for a minimum of contact pressure.

The spring-load of the piston rings is about 10 times lower compared with conventional piston pumps allowing a small leakage, but a much greater live

span.

Disadvantages of this new principle:

It is unknown and not on the market

To the theory:

The inventor found by an mathematical analysis a "magic angle" of 5° for the inclination angle between both rotors

which opens up enough volume, while the distortions, caused by the inclination angle, are still insignificant. This is

the base of this invention.

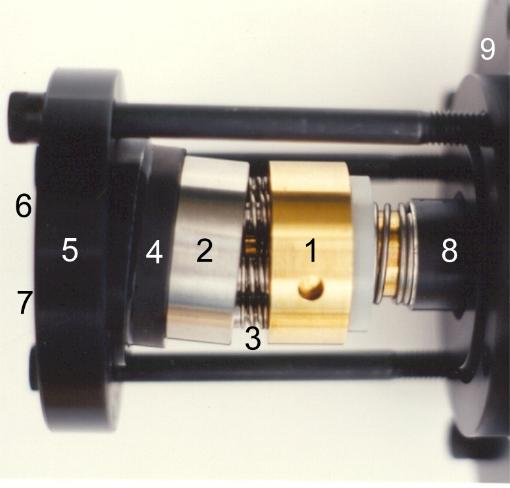

The latest Wolfhart Pump

A total oil-free water pump for 1-10 GPM (adjustable as option), 500 to 4000 rpm at 1000 PSI to 2000PSI

& the first clear water hydraulic motor

The piston rotor with the shaft.....................................................The cylinder rotor

Pistons, piston plate, and drive shaft are one piece.

Both parts are hydraulically balanced and don't need any lubrication - even at high pressure.

These are all moveable parts of the Wolfhart Pump

This is not the only one. The possibilities are endless...

Some rotors (volumes: about 1L/min left, 50 GPM and 1CFM on the right.)

Links to my other developments:

http://www.WolfhartIndustries.com

the ideal principle for the water hydraulic and reverse osmosis

the ideal pump for waterworks and the smallest Wolfhart pump

the ideal principle for oil-free compressors at high pressure

tests of the latest Wolfhart pump

other Wolfhart rotary piston technologies

Environmental friendly two stroke engine

Rotary linear generator (stroke-rotor generator)

A new blowout preventer (BOP) for the oil industry to prevent oil spills

Theory for cause of metastable state

Solution for the energy problem on earth: ultra deep geothermal power plant

Publications:

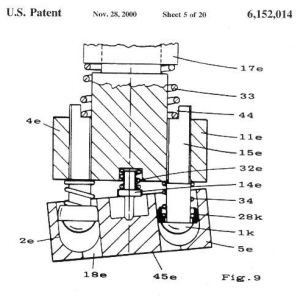

My US-Patent 6,152,014

My invention in "World Pumps"

My patents and other publications

Links to Wolfhart technologies:

http://www.allstar.fiu.edu/aero/WOLFHART.htm

http://www.animatedsoftware.com/pumpglos/wolfhart.htm

The Physicist and Inventor Wolfhart Willimczik

Wolfhart@tampabay.rr.com

©2010 All rights reserved