The Wolfhart Engine

- an advanced two stroke rotary ball piston engine -

Physicist Wolfhart Willimczik

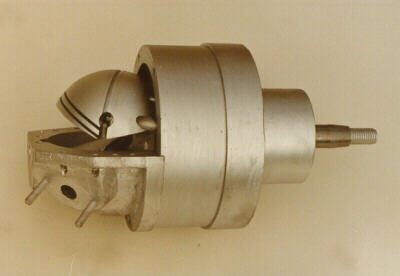

The movement of the piston is recognizable.

(One part of the housing and the wall in the middle are removed. Second kinematik version.)

This was the first model

Drawing taken from German Patent Specification 2519911 and GDR-Patent 113788 of 7.11.1974

Legend:

|

1 - rotary piston |

2 - rotary cylinder |

3 - housing |

|

4 - spherical combustion chamber |

6 - inlet |

7 - exhaust |

|

8 - air intake |

9 - rotary cooling fins |

10 - air outlet |

|

12 - dividing wall |

15 - piston ball bearing |

16 - working chamber |

A spherical piston rotates in combination with a spherical housing, whereby the rotational axes

alone incline towards each other slightly, not unlike a cardan joint. In the process, “strokes” are created within the rotational system, which

are employed to produce periodic volumetric change in working chambers. Two such symmetrical working chambers arise in diametrically opposing sides of

the spherical piston, in sections cut out of the sphere like wedges removed from an orange, one on each side of a smooth dividing wall that extends

into these areas and which is firmly anchored to the casing (external cylinder) that also rotates as part of the system.

Construction:

The spherical piston with the excess for the wall and piston rings.

Kinematics:

In order to understand what goes on inside this device, we will have to take a look at the rotating system. Try to

imagine yourself rotating along with the cylinder rotor. You will observe a swiveling or tumbling motion of the sphere-shaped piston in the

sphere-shaped cylinder. The piston moves back and forth at periodic intervals right up to the dividing wall, while simultaneously swiveling lengthwise

to it. It carries out a tumbling motion that can be differentiated into two pivotal motions occurring vertically on top of one another. One of these

creates the desired stroke motion in the rotating system, the other enables asymmetrical timing. This engine has the kinematics of a single-rotational

engine with the centers of gravity of both rotating parts are at rest. In the coordinate system

at rest there are, in the case of this engine, no to and fro motions. The stroke motions exist only in the co-rotating, body-fixed coordinate system

and generate no oscillating inertial forces. Consequently, this engine produces no vibrations

resulting from oscillating inertial forces. (Consideration of the sealing components is for

the time being left aside as this would go beyond the scope here of general descriptive purposes.)

Two rotors turn, one nested in the other. Contact between the two

occurs via the sealing components. The sliding speeds arising through the motion of both parts tumbling in opposing directions in the co-rotating

system are in fact low. Accordingly, high revolutions per minute are possible (more than 20,000 rpm). Centrifugal and other inertial forces are

however present and may affect particular sealing components at very high speeds.

Seals:

Many a trial of a new principle has come to grief as a result of

seals failing to do their work properly, which is why finding a viable and durable solution was paramount in this instance. The most judicious choice

continues to be for piston rings. They do not provide absolutely impervious barriers, but are serviceable since pressure in the cylinder need only be

briefly maintained. (The more revolutions per minute, the more negligible the leakage factor becomes, as it can be regarded as a time

constant.)

The engine’s

seals

I used 2 compression rings and 1 oil-ring on each piston.

For these reasons, at the circumference of the spherical piston I

use sections of piston compression rings, oil control rings and oil scraper rings respectively, at whose ends minute spaces perform the function

ordinarily fulfilled by the ring gaps. At the center of the sphere, a straight, swivel-mounted elongated seal, (11) pivots up and down from its own

central point at right angles to and in gliding contact with the dividing wall, (12).

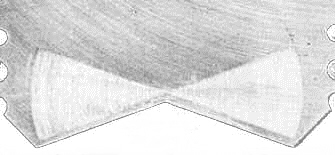

5. Here the

butterfly-winged signs of abrasion caused to the dividing wall by the central seal are clearly visible, reflecting the lateral pivotal motion of the

piston along the dividing wall; also the blackening of the dividing wall as a result of combustion can be detected.

Initially, I employed pointed seals, which has been not robust

enough. I was also disadvantaged through not having proper machine tools at my disposal for the manufacture of parts to the degree of the required

exactitude. I thus next intended to compromise by attempting to use semi-circular seals, which are more robust and able to withstand forces easier.

But this was not to come about, as the SSD was once more directing events...

Lubrication:

As is the case with a standard four-stroke engine, an oil bath is

situated behind the piston, which in turn is fitted with oil scraper rings. Here, attention must merely be paid to ensuring that the oil gathers

externally, because of the rotation. In fact, if outlet ports are placed in this area for the oil, an oil pump can be potentially dispensed with.

Otherwise, oil that is pumped into the center also carries heat from the interior to the exterior, which in turn can be utilized for cooling purposes.

Cooling:

Plain and simple forced air lends itself as a cooling system here.

There are cooling fins attached to the outside of the cylinder rotor that simultaneously act as fan blades. Cooling air is sucked in at the

rear and through channels, (8) inside and blown out through holes, (10) in the housing, (3). (An oil circulation system could also be brought in for

cooling purposes.) A water-cooling system would not be so easy to bring about, but would also be feasible. The manner of cooling depends on whether

the intention is to use the engine to power a lawnmower or a racing car.

Operation and Timing:

The drawing refers to a normal two-stroke process, i.e., one working chamber functions as the charge pump, the other as the engine. Air reaches the charge pump after passing through a port, (6), and is then compressed into the side of the engine via ducts (not visible) - after the outlet, (7) has been closed by the piston and piston rings. Through the swiveling motion of the top edge of the piston this is achieved easily, with the engine developing asymmetrical timing as a result, similar to that of a standard four-stroke engine. This is a great advantage over a normal two-stroke engine. The gas is then fired in the sphere-shaped combustion chamber, (4). Near the bottom dead center, the outlet is again opened and then shut again, then the cycle,,,, takes place, and so on.

The ignition voltage is transferred here through non-contact, which is unproblematic. (On

the contrary, it increases the effectiveness of the spark plug.) By virtue of the better timing diagram and the significantly higher volumetric

efficiency – the “crankcase pump” here having almost no dead volume – a single combustion stroke here produces more power than is the case

with a standard two-stroke engine, for which reason the engine output per unit of displacement here is higher. Moreover,

the number of revolutions per minute can be increased even more, the bearings not being subject to the otherwise high inertial forces, which in turn

raises the engine output per unit of displacement. It would thus be not only a prime mover for lawnmowers and standard motorcycles and cars, but also

a high-performance engine for racing drivers.

For standard cars, the engaging/disengaging of individual cylinders would be more easily

achievable, since they are anyway connected to each other via cogs, gear wheels or similar means.

Other operations corresponding more to those of a turbine would also be feasible.

Different positions of the piston

(The wall etc are removed)

I invented this engine in the 1960s in direct competition to the Wankel engine being developed at the time. Comparison to a standard reciprocating piston engine of that era is therefore not made here. If my rotary engine were to be compared to today’s versions of standard piston engines, I would do so using several new principles I have developed since my original type. These operate with asymmetrical control diagrams and direct lubrication, as in my US patent 6,152,014

Comparison Between

Wankel and Wolfhart Engine

|

Wankel Engine |

Wolfhart Engine

|

Rotary Piston Engine

The center of gravity of moving parts (piston) rotates in a

circular path |

Rotary Piston Engine

The center of gravity of moving parts (piston and cylinder) is at

rest |

|

Three-chamber four-stroke operational principle with asymmetrical timing diagram |

Two-chamber two-stroke operational principle with asymmetrical timing diagram |

|

Linear sealing with pointed sealing strips |

Sealing via piston rings (segments) and flat sealing strips |

|

High sliding speeds of sealing strips |

Low sliding speeds of sealing strips |

|

Fuel needs oil added to it |

Direct oil lubrication as with standard four-stroke reciprocating engine |

|

High revs per minute not possible |

High revs per minute possible |

The report on my inventions 1975

There my invention runs as a

water pump vacuum

pump compressor

Video clip from 1975 “News from Science and

Technology”

RealMedia (rm) 1,8MB

or Media

(avi) 4,2MB and smaller picture

My TV debut along with my machine was to serve as a foretaste of a longer report on the invention intended for broadcast at a later date. This however never materialized. My engine was never seen. I was subsequently expelled from the Academy of Science (layoff) , jailed and divorced by coercion and all my inventions barred as “a matter of state security". My manuscript written in 1975 remained unpublished. The only recorded views concerning my engine still extant.

Physicist Wolfhart Willimczik

info@WolfhartIndustries.com

©2014 All rights reserved

WolfhartIndustries

videos of my inventions

tests of the latest Wolfhart pump

the ideal principle for the water hydraulic and reverse osmosis

the ideal fuel pump

the ideal pump for waterworks and the smallest Wolfhart pump

the ideal principle for oil-free compressors at high pressure

other Wolfhart rotary piston technologies

Publications:

My latest US-Patent 6,152,014

My invention in "World Pumps"

My patents and other publications

Links to Wolfhart technologies:

http://www.allstar.fiu.edu/aero/WOLFHART.htm

http://www.animatedsoftware.com/pumpglos/wolfhart.htm